Installing Spotlight Cam Pro (2nd Gen) Wired

Install Spotlight Cam Pro (2nd Gen) Wired by following these steps.

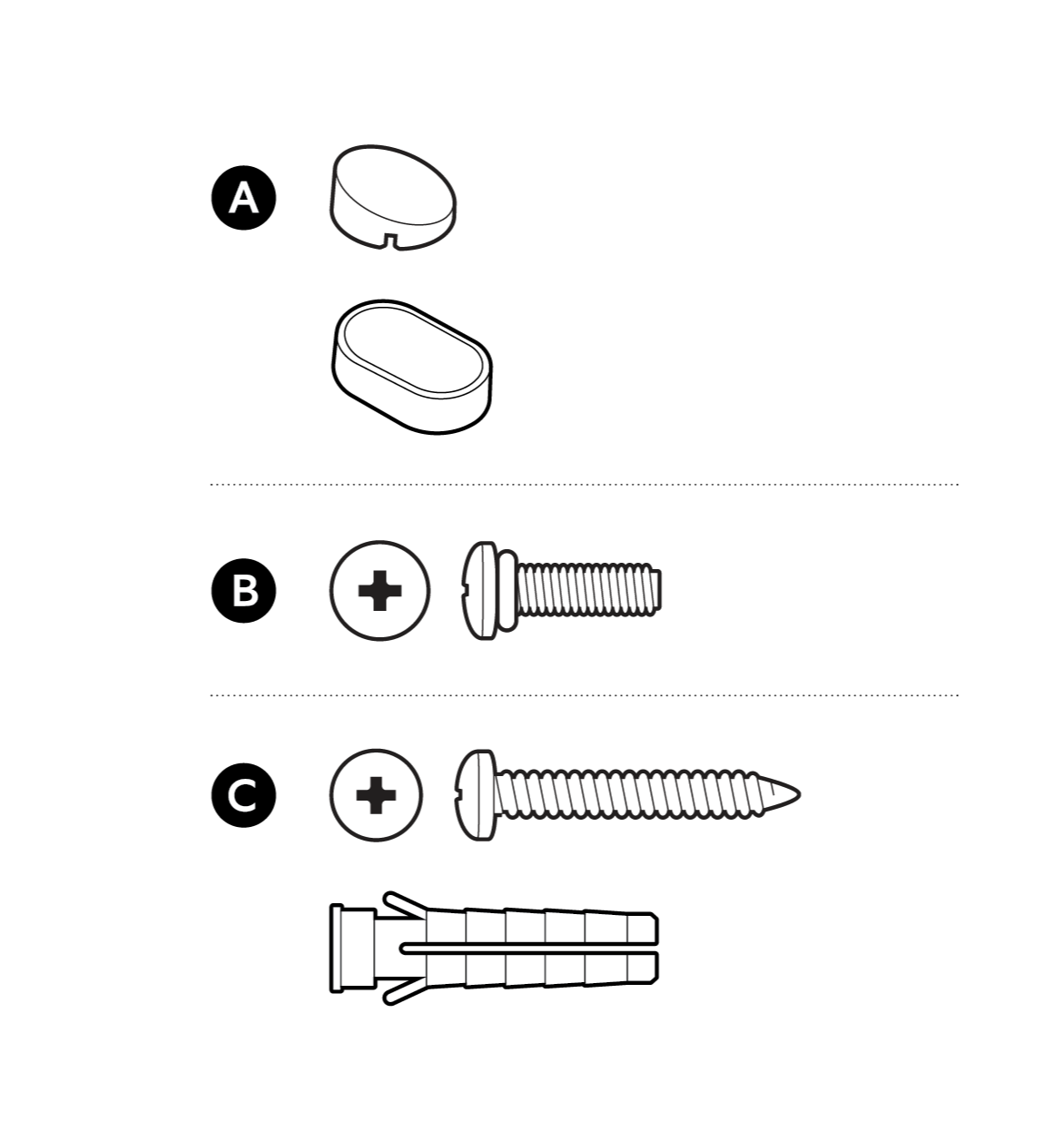

View or download the user manual for Spotlight Cam Pro (2nd Gen) WiredHardware included

Tools needed

Phillips-head screwdriver

Caulk gun

Drill with a 6 mm (1/4 in) masonry bit (optional)

1. Remove the protective wrap.

2. Download the Ring app.

3. Scan the QR code on your device.

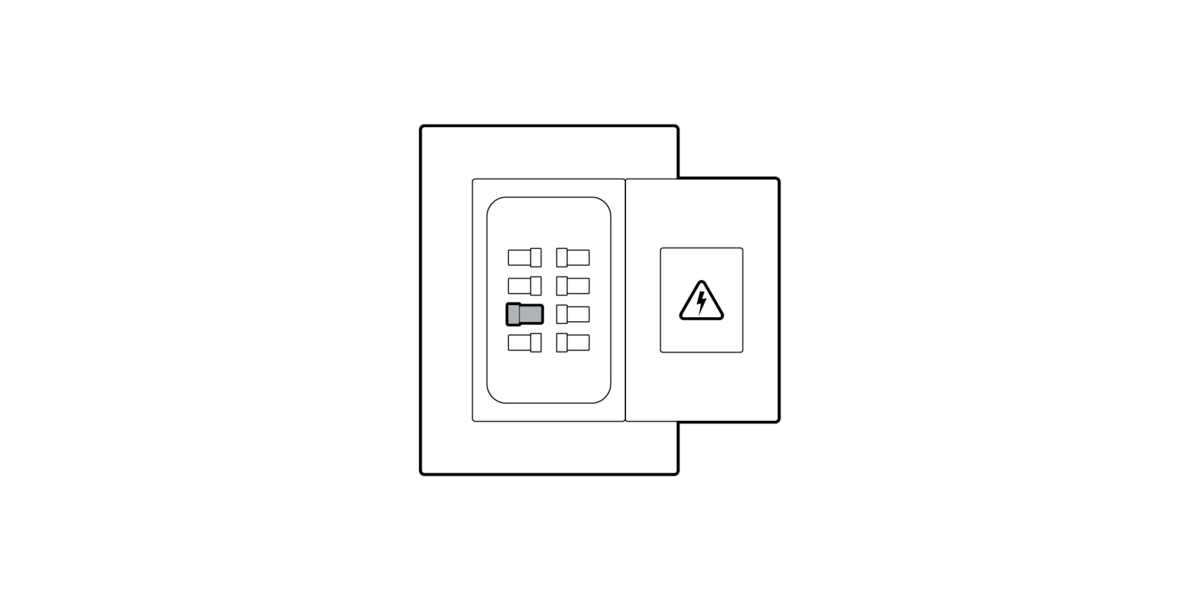

Hardwired Kit installation

Before you begin installing your Hardwired Kit, make sure that you’re following safety code standards.

WARNING: Risk of electrical shock. Installation and wiring must be performed by a licensed electrician in Australia and New Zealand, and may be required in other countries. Refer to your local laws and building regulations before performing electrical work; permits and/or professional installation may be required by law.

Turn off power at the consumer unit before installing.

Verify that the supply voltage is correct. Connect product to a 100 to 240 VAC 50/60 Hz power source.

The earth wire must be connected to the product. DO NOT INSTALL if a working earth connection is not available.

Do not connect this product to a dimmer switch or timer.

CAUTION: Risk of fire. Do not install near combustible or flammable surfaces. The Hardwired Kit must be installed on a wall or eave.

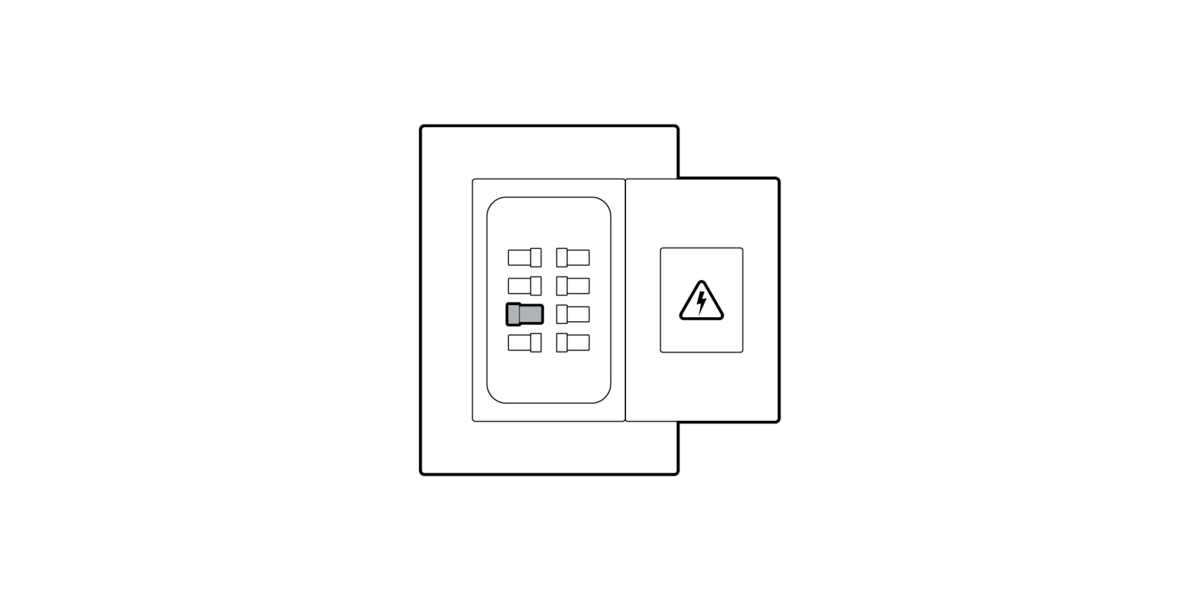

1. Shut off power at the breaker.

Note: If your power system is classified as OVC III, please check the building “Distribution Panel”, Ex switch panel has installed Surge Protectors. Ensure that the surge protector is an IEC 61051-2 certified Surge Protector to reduce Mains Transient Voltage to Overvoltage Category II (2500 V pk or lower) before connecting to all AC Inputs. If there is no Surge Protector, do not install Hardwired Kit without one.

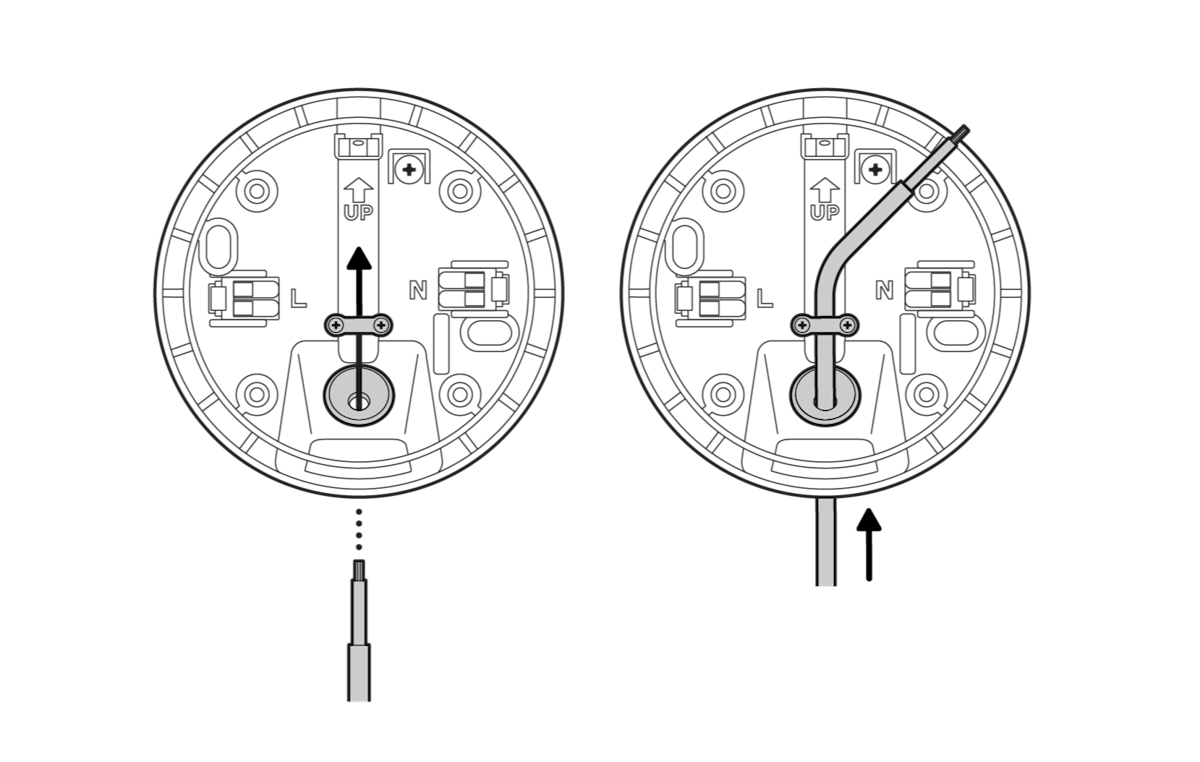

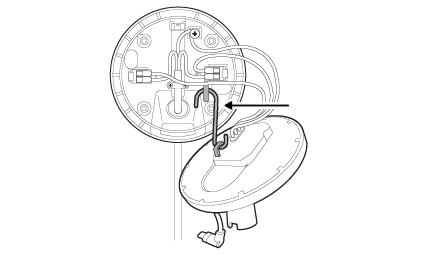

2. Feed wire through grommet.

Note: Use a minimum 18AWG or higher round 3-core cable with outer diameter of 6-7 millimetres and core diameter of 0.75-1 millimetres.

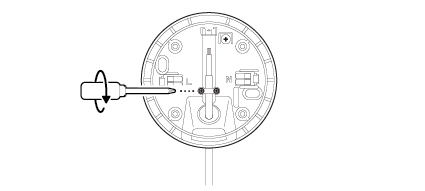

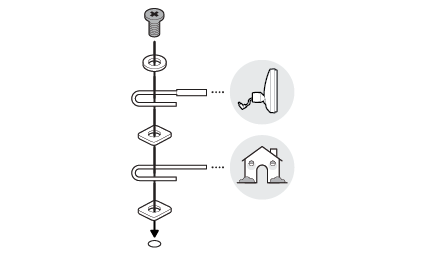

3. Tighten wire fastener screws.

WARNING: The pressing plate should be over the cable insulation, and not over the individual wires.

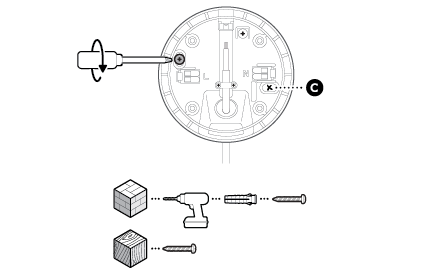

4. Use level and mark screw holes.

5. Install junction box.

6. Cover screws with rubber caps.

Optional: Use the built-in hooks to hold the S-hook.

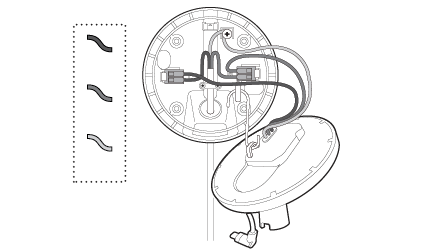

7. Connect wires.

Fasten earth screw with a minimum torque of 0.4N/m.

Connect the brown (L) and blue (N) wires.

Note: If ever needed to remove wires: Remove the brown (L) and blue (N) wires. Then, remove the yellow wired mount bonding conductor wire and the home protective earthing conductor wire.

WARNING: Please follow standard electrical code in your country. Depending on the age of the home, the wires may not match the colours shown below. Consult an electrician if you are unsure.

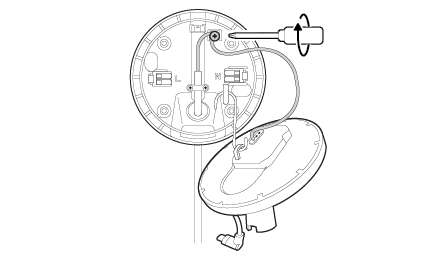

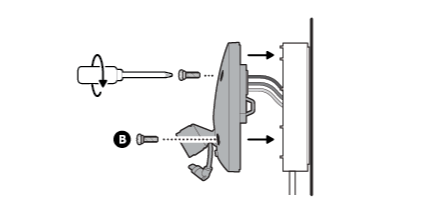

8. Tuck wires and install wired mount.

9. Tighten screws until fully sealed.

Then, tighten the screws into the wired mount until the foam backing fully seals the junction box to prevent water from entering. (1.37-1.47N/m of torque force)

10. Apply cosmetic screw plugs.

11. Restore power to the breaker.

Camera installation

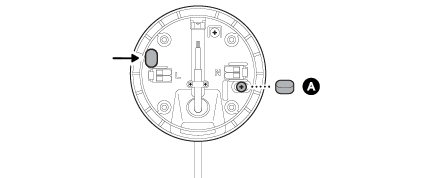

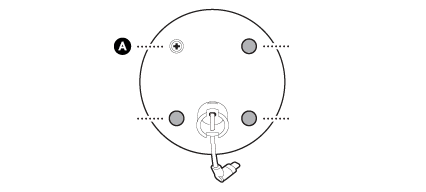

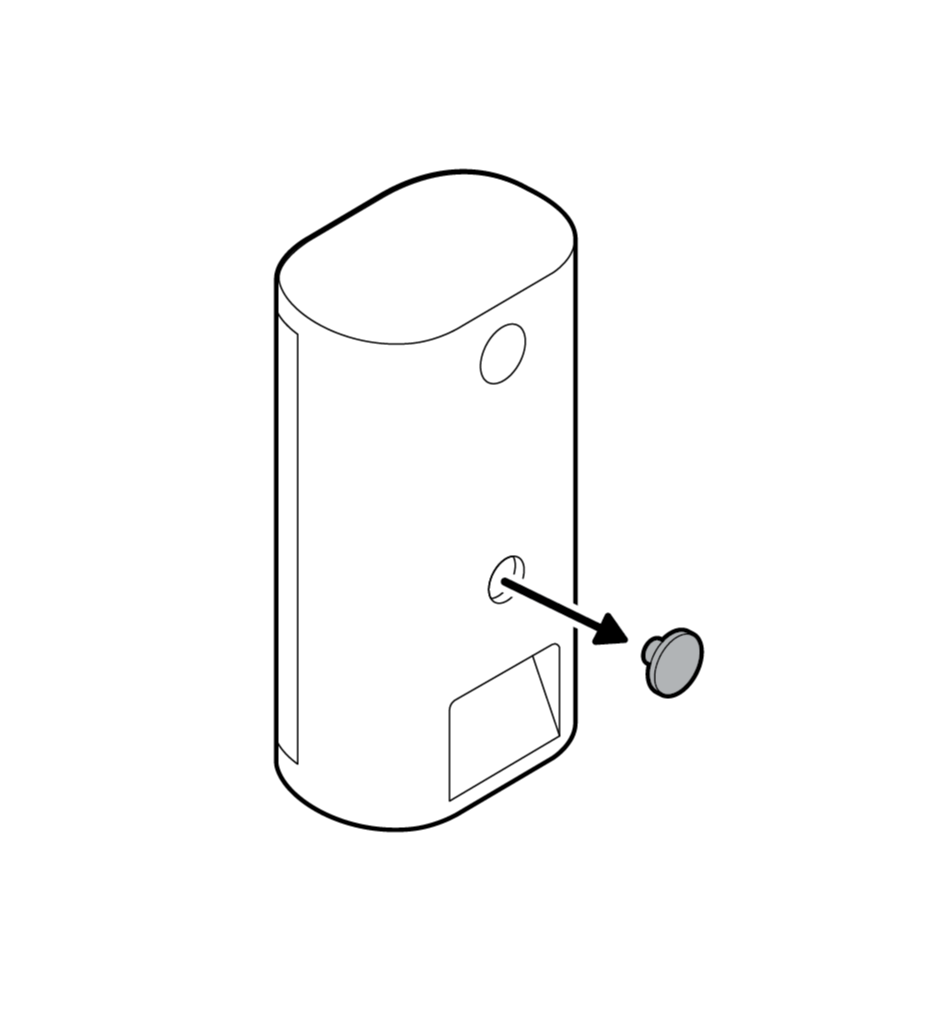

1. Remove the middle rubber cap on the back of your camera.

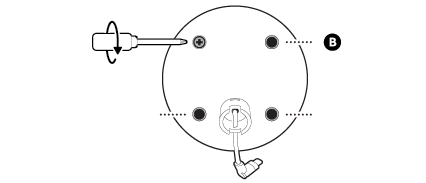

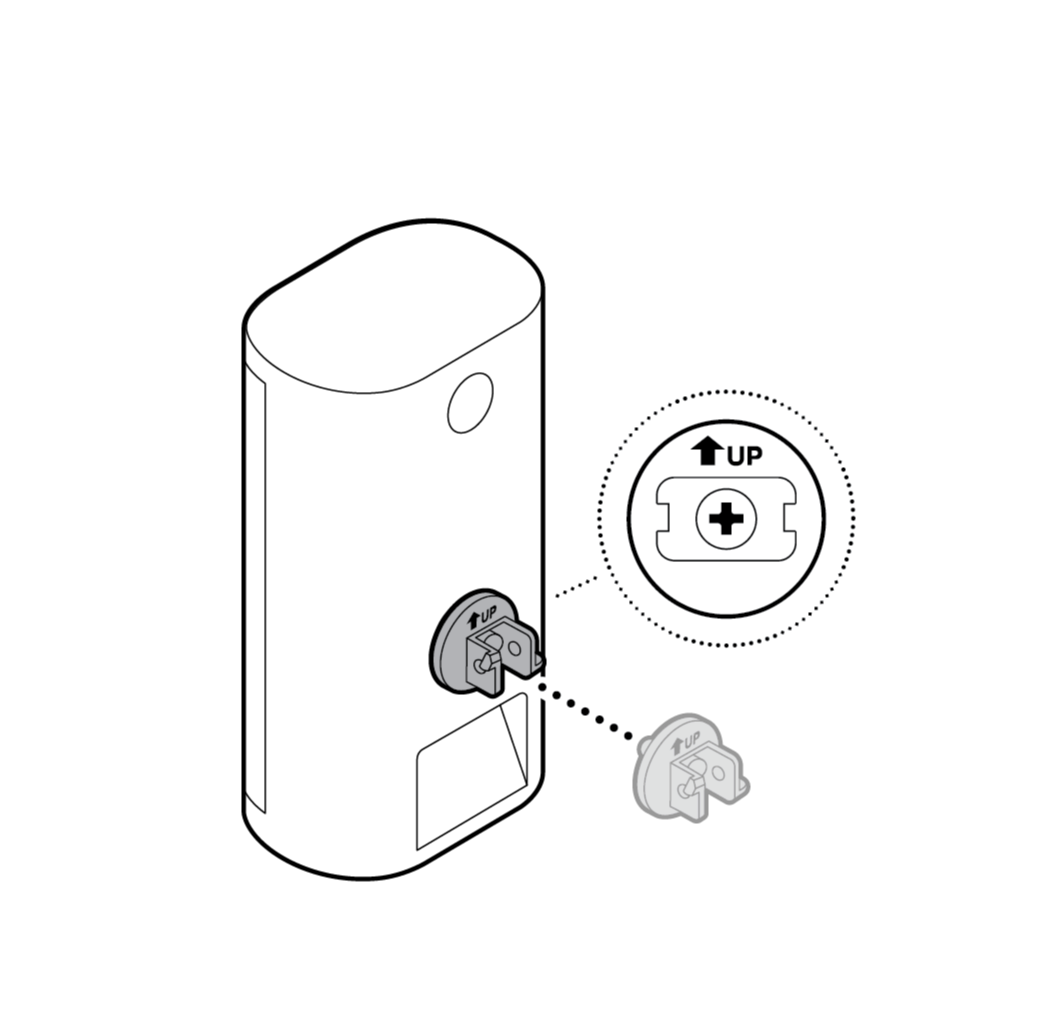

2. Tighten the included hex joint onto the back of your camera, ensuring the UP arrow is pointing up.

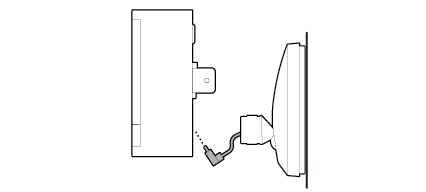

3. Plug the USB-C cable on the junction box cover mount into your camera, ensuring it is fully inserted.

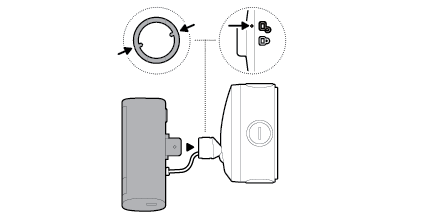

4. Align the locking indicators on the hex joint and the junction box cover mount and insert.

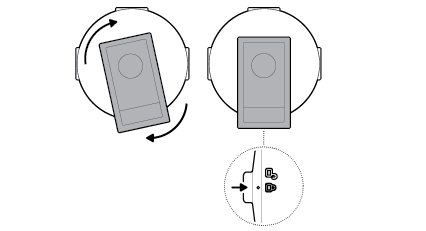

5. Turn until your camera locks in place.

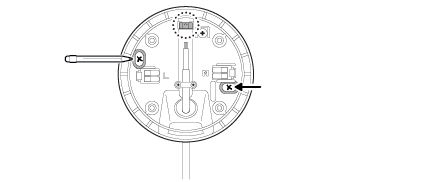

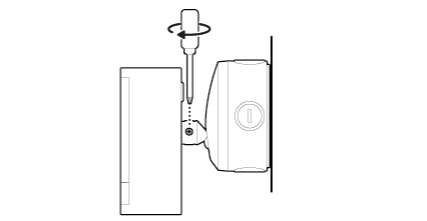

6. Tighten the security screw.

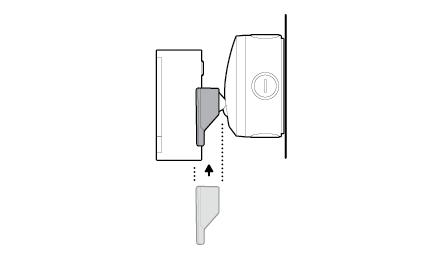

7. Install your camera’s decorative cover by sliding until you hear a click to secure.

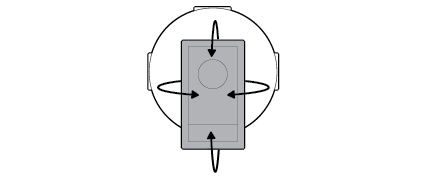

8. Adjust your camera’s position, if necessary.

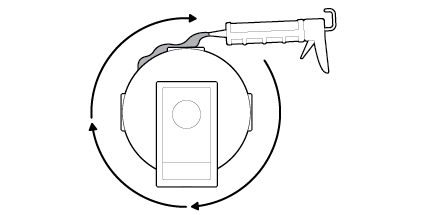

9. Apply proper silicone or caulk around the junction box knockouts, between the junction box and junction box cover mount, and between the junction box and mounting surface to seal any gaps.

10. Restore power to the breaker.